It’s our number one question: How expensive is aluminum piping compared to copper, steel or iron pipe? You might be surprised. When you consider the total cost of ownership, including installation costs, aluminum piping is the most affordable option on the market — yes, even cheaper than black iron piping. In fact, factoring in the longevity, durability and low maintenance of aluminum compressed air system piping, the total lifetime cost of ownership is unbeatable by anything else on the market. Let’s break down the costs of the distribution piping material options and see why.

Calculating the Costs of Distribution Piping

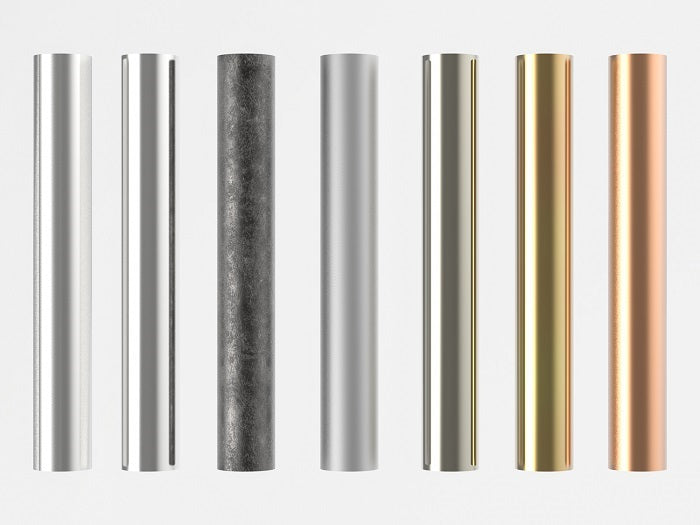

When comparing the total lifetime costs of aluminum piping systems, such as the blue pipe systems offered by Unipipe, to those made of black iron, steel, or copper, several key factors must be considered. These factors will impact not just the initial installation costs but also the long-term expenses associated with maintenance, durability, and operational efficiency. Here’s what you should keep in mind.

Initial Installation Costs

Installation costs for aluminum pipe vs. iron, steel or copper must factor in both material costs and labor costs for installation.

- Material Costs: The raw material cost for each type of pipe can vary widely, with stainless steel and copper generally being the most expensive and black iron or galvanized steel being less so. Aluminum falls somewhere in between, a little more expensive than black iron but substantially cheaper than copper or stainless steel.

- Labor Costs: Labor costs are where aluminum truly shines. Unipipe aluminum piping systems can be installed in half the time of black iron, steel or copper, with no threading, grooving, welding or soldering. That means the system does not require installation by a skilled plumber or welder, unlike iron, copper or steel options. Aluminum piping systems are also lighter and easier to handle than iron or copper, which means fewer people required for handling and fewer anchors to install.

Installation Costs: Aluminum Pipe vs. Stainless Steel, Black Iron and Copper

| Material | Material Cost | Labor Cost | Total |

|---|---|---|---|

| Stainless Steel 304 | $11,170 | $12,000 | $23,170 |

| Copper Sweat | $8,550 | $12,000 | $20,550 |

| Black Iron Schedule 40 | $4,050 | $12,000 | $16,050 |

| Unipipe | $6,470 | $6,000 | $12,470 |

Based on a simple system with 200’ of 2” main piping with 10 air drops that have an isolation valve and two 1/2” connecting.

Durability and Lifespan

When looking at total cost of ownership for distribution piping, it’s also important to look at how long the system can be expected to last and how much maintenance will be required over its lifetime. Once again, aluminum performs exceptionally well — equal to stainless steel, at less than half the cost.

- Corrosion Resistance: Aluminum pipe is naturally resistant to corrosion, which can significantly extend its lifespan and minimize the risk of leaks over the life of the system. Black iron is highly prone to rust, as is regular steel (though galvanized steel will last longer). Copper is generally corrosion-resistant but can be susceptible to certain types of corrosion, like pitting, when exposed to moisture or certain chemicals. Stainless steel, like aluminum, is long-lasting and corrosion-resistant, though at a substantially higher price.

- Maintenance Requirements: Due to their resistance to corrosion and leaks, aluminum piping systems often require less maintenance over their lifetime. Black pipe, in particular, requires frequent leak repair and periodic replacement of leaky fittings or corroded pipe sections. Aluminum, in contrast, can be virtually maintenance-free for many years.

System Efficiency

System efficiency is an important consideration when choosing pipe for compressed air or inert gas distribution systems. The right piping can reduce overall energy costs.

- Energy Efficiency: Aluminum piping, with its smooth interior walls, minimizes pressure drops more effectively than black iron or steel, which can corrode and create rough surfaces inside the pipe. This efficiency can lead to lower energy costs for compressed air systems, as less energy is required to maintain the desired pressure.

- Leak Resistance: Another factor for compressed air systems in particular is leak resistance. In the average compressed air system, about 30% of compressed air is wasted, much of it due to leaks in piping, especially at joins. Unipipe’s unique grip ring system provides a virtually leak-free seal that is 5x more secure than other aluminum piping systems. That translates to less air loss and less energy used for compressed air production.

System Modification and Expansion

Aluminum piping systems are relatively easy to modify and expand due to their modular design and easy-connect fittings. Steel and black iron systems, on the other hand, may require cutting, threading, and welding for modifications, which can be more labor-intensive and costly. Copper offers some flexibility but typically requires soldering for modifications. Unipipe’s reusable clamp ring fittings make it simple to reconfigure or add to your distribution system with minimal cost and downtime.

Environmental Factors

Aluminum, steel, and copper are all highly recyclable materials, which can be a consideration in the total lifecycle cost and environmental impact of the piping system. The ease of recycling and the residual value of the material at the end of its life can offset some of the initial investment. Aluminum is one of the most recyclable materials available. Its recycling process is highly efficient, requiring only about 5% of the energy needed to produce the same amount of aluminum from raw bauxite ore. Recycled aluminum retains all its properties, meaning it can be recycled indefinitely without losing quality. This makes aluminum pipes an exceptionally sustainable choice for compressed air piping systems and other applications.

Choose the Affordable Piping Option: Aluminum

When comparing the total lifetime costs of Unipipe aluminum compressed air piping systems with black iron, steel, or copper piping systems, it’s essential to look beyond initial expenses and consider factors like durability, maintenance, operational efficiency, and the potential for system modifications. Aluminum piping from Unipipe offers a compelling combination of low maintenance, high durability, and efficiency that can lead to cost savings over the system’s life, making it an attractive option for many applications.

Contact us for a quote or to request a reseller demo kit!