Unipipe aluminum pipe systems can be used for a wide range of applications, including compressed air systems, vacuum systems and nitrogen or inert gas distribution. Why choose aluminum for compressed air system piping? We’ve got ten great reasons for you.

1. Superior Corrosion Resistance

Corrosion is a major problem in iron or mild steel piping, leading to system leaks, blockages, reduced airflow and loss of pipe integrity. In addition, a buildup of corrosion in the piping system can contaminate compressed air, gas or fluid streams with debris and rust particles, compromising air quality and causing damage to downstream equipment and processes. Aluminum pipes are inherently resistant to corrosion, even in harsh environments where exposure to moisture, chemicals or corrosive substances is common, leading to better air quality and reduced energy costs.

2. Smooth Interior Surface and Enhanced Air Quality

Aluminum air pipes typically have a smooth interior surface, which minimizes friction and pressure drop as air or fluids flow through the system. This results in more efficient operation and reduced energy consumption compared to piping materials with rougher surfaces, including galvanized steel. The smooth surface of aluminum pipe systems also prevents buildup of debris, scale and contaminants inside the pipes, maintaining consistent flow rates and improving overall system performance.

3. Lightweight for Easy Handling and Installation

Unipipe aluminum pipe systems are significantly lighter than traditional metal piping such as a black iron or stainless steel pipe system, making it easier to handle, transport and install. This lightweight construction reduces labor costs and installation time, especially in overhead or elevated applications. The lightweight nature of aluminum piping also makes it suitable for portable or mobile applications where weight is a concern, such as remote locations or temporary setups. Unipipe is 75% lighter than iron pipe, so fewer anchors are needed, and pipes up to 6” in diameter can be easily handled by a single person.

4. Low Maintenance Requirements

Due to its corrosion resistance and durable construction, aluminum pipe from Unipipe requires minimal maintenance over its lifespan compared to black iron or copper pipe systems. Routine inspections and cleaning are typically sufficient to keep the system operating at optimal performance, reducing downtime and maintenance costs. The low maintenance requirements of aluminum piping make it a cost-effective and hassle-free solution for compressed air, fluid or gas distribution systems in industrial settings.

5. Secure, Leak-Free Connections

Modern blue pipe systems utilize push-to-connect or quick-connect aluminum pipe fittings, providing secure and leak-free connections in a pressurized system without the need for welding or threading. This ensures airtight seals, minimizing system leaks and improving efficiency and performance. The leak-free aluminum pipe fittings help minimize energy losses, resulting in lower operating costs and improved productivity. Unipipe’s proprietary clamp-and-ring design provides a secure 360° connection that is five times more secure than other aluminum piping systems on the market.

6. Quick and Easy Installation for Lower Installation Costs

Installation of black iron, copper, and stainless steel piping systems typically involves welded, soldered or threaded connections, which require skilled workers and specialized tools and expertise. This drives up labor costs and installation timelines. Compared to other materials for compressed air, aluminum pipe systems are modular, easy to install with basic tools, and do not require any hot work. The lightweight construction and push-to-connect fittings make installation quick and straightforward, lowering installation costs and downtime during system setup. Unipipe’s unique clamp system was designed to speed up installation; a Unipipe aluminum air pipe system can be installed in about ½ the time of traditional iron piping and ¼ of the time of copper piping!

7. Uncompromised Safety

Aluminum air pipe is safe for use in compressed air, fluid or gas distribution systems. Unlike certain plastics or metals, aluminum does not leach harmful chemicals or contaminants into the conveyed materials. It is also a strong and durable material, capable of withstanding high pressures safely. Plastics degrade over time, increasing the cost of a dangerous rupture (which is why some plastics, such as PVC, cannot be used for compressed air or gas piping). Unipipe’s aluminum pipe systems hold up over time, even in harsh conditions, for a safe and reliable system for transporting high-pressured air. UnpipeHP has the highest-rated working pressure available and is safe for gas or fluid applications up to 1015 PSI.

8. Flexibility for Customization and Remodeling

The flexibility of Unipipe aluminum air piping enables customization of system designs, adaptation to space constraints, and integration with existing infrastructure, providing versatility and efficiency in various applications across industries and settings. Aluminum piping systems are modular and easily configurable, allowing for flexible layouts and modifications to accommodate changing needs or expansion of compressed air, fluid or gas distribution systems.

9. Lower Lifetime Costs

While aluminum piping systems may have a higher initial cost compared to traditional metal pipes, their lower maintenance requirements, improved energy efficiency, durability and longevity can result in lower lifetime costs over the lifespan of the system. Factors such as reduced labor costs during installation, energy savings, minimal maintenance and longer service life contribute to the overall cost-effectiveness of aluminum piping systems compared to traditional metal pipes. When considering lifetime costs, aluminum piping systems offer a favorable return on investment that makes them the preferred choice for many applications.

10. Commitment to Sustainability

Aluminum is a recyclable material, making it an environmentally friendly choice for compressed air, fluid, or gas distribution systems. Additionally, aluminum piping requires fewer resources for manufacturing and disposal compared to other various piping materials. By choosing aluminum piping, companies can contribute to sustainability efforts and reduce their environmental footprint.

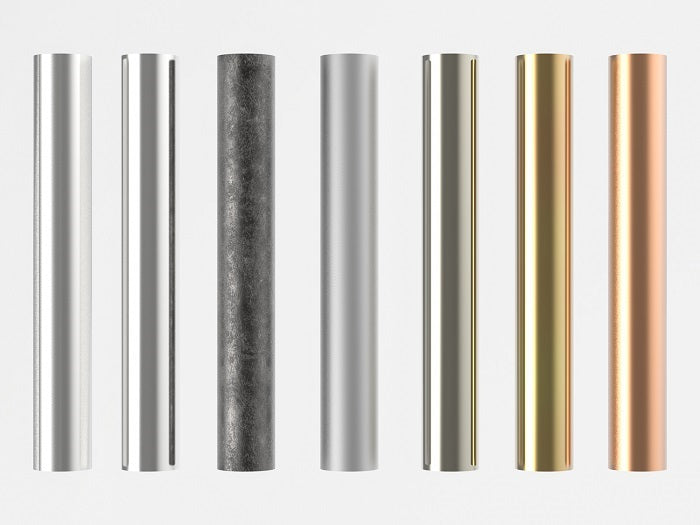

Benefits of Aluminum Pipe vs. Black Iron, Copper, Steel and Plastic

How does aluminum piping compare with other pipe material alternatives? Here is a summary of some of the benefits of aluminum pipe vs. black iron, steel, plastic or copper alternatives for compressed air pipeline systems and other applications.

Where Are Aluminum Piping Systems Used?

Aluminum piping offers numerous benefits for compressed air systems, nitrogen or inert gas transport, and other forms of fluid delivery. That’s why most compressed air installations today, along with other pressurized gas delivery systems, are moving to affordable and versatile blue pipe systems made of aluminum. Aluminum pipe systems are widely used throughout the manufacturing industry, including general and automotive manufacturing, aerospace industry applications, textile production, and more. Blue pipe systems are also used in the energy sector for various gas and fluid conveyance applications. Because aluminum piping doesn’t corrode, it is also suitable for applications requiring high air quality, such as food processing and pharmaceutical manufacturing.

Ready to Switch to Aluminum Pipe from Unipipe?

Unipipe is the #1 distributor of safe, efficient aluminum piping systems for compressed air, nitrogen, vacuum and high-pressure gases and fluids. We work with manufacturers, resellers and installers all over the country on both new builds and retrofit piping systems. Contact us to request a demo kit or talk to one of our piping system experts today.