What’s the best compressed air piping material? Compressed air pipe must be strong enough to withstand high pressures and corrosion resistant for a longer service life. It also should be easy to install and affordable. Which piping material fits the bill? There is a clear winner!

Compressed Air Piping Options

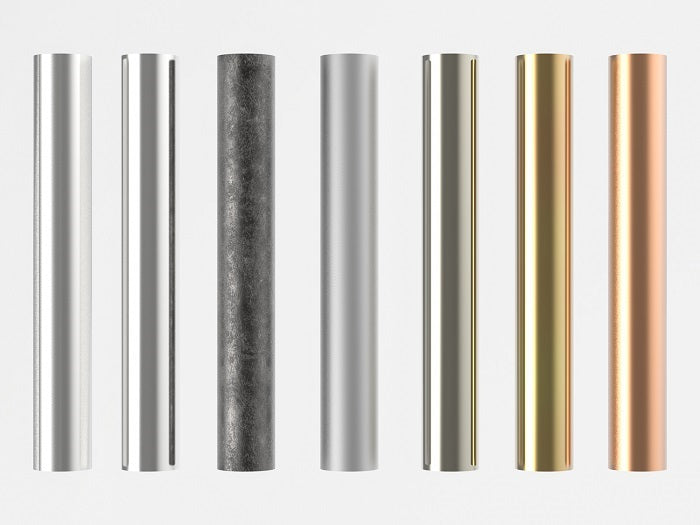

There are many options when it comes to compressed air piping, including iron, copper, stainless steel, aluminum and plastic. Deciding what pipe to use for compressed air or gas distribution is an important part of compressed air system design. The selection of compressed air piping material in industrial settings requires careful consideration of various factors, including cost, durability, installation requirements and environmental suitability. Let’s explore some of the options for compressed air systems.

Aluminum Piping

Aluminum piping (like the blue pipe systems offered by Unipipe) is rapidly becoming one of the most popular options for compressed air systems. Aluminum piping offers an outstanding balance of light weight, corrosion resistance and ease of installation, making it an excellent choice for a compressed air piping system.

- Pros: Aluminum is lightweight and flexible, facilitating easy installation and modification. It is also highly corrosion-resistant, ensuring clean air delivery and system longevity. Unipipe aluminum compressed air piping systems are designed with specialized quick-clamp fittings, so they do not require skilled labor or welding to install.

- Cons: While aluminum has higher initial costs than black iron, galvanized steel or plastic, savings on installation, maintenance and energy efficiency can offset this. It is important to use the correct fittings for the piping system.

Plastic Piping

Plastic pipes are lightweight, corrosion-resistant, and relatively inexpensive compared to metal pipes, making them suitable for certain compressed air systems. However, they do not offer the safety or longevity of metal piping.

IMPORTANT SAFETY NOTE: PVC piping is NOT rated for use with compressed air and will shatter at high pressures, creating a risk of property damage, serious injury or death.

People also ask “can PEX pipe be used for compressed air?” - and the answer is no. PEX pipe, like PVC, is rated for fluids only. Using PEX pipe for compressed air may cause a safety issue. Before installing a plastic piping system, always check with the manufacturer to be sure it is rated for compressed air use.

- Pros: Plastic is lightweight and corrosion-resistant. It is also relatively inexpensive and easy to install without skilled labor or special tools.

- Cons: Plastics may not be suitable for high-pressure or extreme temperature applications. They are also susceptible to degradation from UV light exposure. Plastic pipes are not as durable as metal pipes, resulting in a shorter service life in a compressed air system.

Black Iron Piping

Black iron is the most traditional material for compressed air piping, and many manufacturers still rely on it. Iron pipe uses traditional joins and must be installed by a plumber.

- Pros: Black iron is strong, durable and cost-effective, with easily available fittings.

- Cons: Iron requires a skilled plumber or welder to install. It is also very heavy, requiring extensive anchoring for suspended systems. Most critically, black iron is prone to leaks along joins and seams and is highly susceptible to corrosion, which can foul air lines and cause blockages and pressure drop.

Galvanized Steel

Can you use galvanized pipe for compressed air? Galvanized steel is a step up from black iron piping for compressed air systems. Galvanized pipe is coated with zinc for added corrosion resistance. Like iron pipe, it must be fitted by a skilled plumber or welder.

- Pros: Galvanized steel pipes are durable and can withstand high pressures. They are relatively inexpensive and readily available. They can also resist corrosion to some extent.

- Cons: Over time, galvanized pipes can corrode from the inside, leading to reduced airflow and potentially contaminating the compressed air with rust particles. Installation can be labor-intensive, and they may require regular maintenance to prevent corrosion buildup.

Stainless Steel

Stainless steel piping is a durable, if costly, alternative for a compressed air piping system. Stainless steel is sometimes recommended for food or pharmaceutical applications where compressed air is in direct contact with product. It requires fitting by a skilled plumber or welder.

- Pros: Stainless steel compressed air pipes offer excellent corrosion resistance and are suitable for applications where cleanliness and purity of the compressed air are critical. They have a long lifespan and require minimal maintenance.

- Cons: Stainless steel pipes are the most expensive option among the materials listed here. They are also heavier than most other materials, which can make installation more challenging and costly.

Copper

Can copper pipe be used for compressed air? Copper piping is sometimes used for compressed air distribution, though it is another costly alternative. Lighter than black iron, copper also requires installation by a skilled plumber or pipefitter.

- Pros: Copper pipes are lightweight, corrosion-resistant and can handle high pressures.

- Cons: Copper pipes are more expensive than iron, galvanized steel or aluminum, which can increase installation costs. Skilled labor for installation and changes can also be costly. Copper pipes may be susceptible to damage from acidic or alkaline substances.

And the Winner Is: Modern Aluminum Piping Systems for Compressed Air

While many manufacturers still rely on traditional black-iron piping, a modern aluminum piping system offers many benefits for an air compressor system. Aluminum is naturally durable and corrosion resistant, offering years of trouble-free performance and clean delivery of compressed air. With a smooth interior surface, aluminum pipes also ensure efficient airflow with low pressure drop in the compressed air system.

Aluminum piping systems from Unipipe are:

- Fast and easy to install or modify without specialized tools or skilled labor.

- Lightweight and easy to handle.

- Resistant to leaks and corrosion.

- Flexible and adaptable for any compressed air application.

- Durable and low maintenance for extended service life.

Upgrade to a Modern, Durable Aluminum Piping System Today

Whether you are looking for compressed air piping for a new build or planning to replace an older air distribution system, the Unipipe aluminum piping system is the obvious choice. The Unipipe system is easy for builders and installers and offers years of problem-free performance for compressed air users. With a wide range of pipe sizes (3/4” to 10”) and the highest-rated working pressures (up to 1015 PSI with UnipipeHP), Unipipe can meet even the most demanding project specifications.